Products

Climatic Test Chamber

The climatic chambers are a great choice for cyclic low, high temperature and humidity tests. Built with the highest quality and reliability, this chamber can meet the most stringent testing needs of various international standards such as ASTM, IEC, MIL, DIN, etc.

Designed and developed by chamber is engineered with the latest simulation technology with an objective to offer unparalleled testing experience to the customers. The highly responsive touchscreen controller ( HMI Series) used in this chamber is bundled with whole lots of features, such as Chamber Analytics, On-demand cooling, onscreen diagnostics, safety alarms. It is also integrated with networking ports such as Ethernet, RS 232, RS 485 along with 1GB SD card for test data storage. The features also include the integration with third party software such as NI/Lab view.

The biggest advantage is that they are highly flexible for customization. Every test follows a set of procedures as per the defined test standards (ASTM, IEC, MIL, etc.) and sometimes a standard climatic chamber might not be enough to conduct a particular test. Our engineers understand this need of the industry and offer the highest level of customization such as design modification, high performance ramp rates or integration with other applications such as Climatic Chamber with UTM integration, Climatic Chamber with Vibration Integration.

We are an suppliers of high quality Hot and Cold Chamber. The inner walls of these products are insulated with high quality raw materials, to maintain constant hot or cold temperatures inside the chambers. These products are offered with digital controllers cum indicators with effective sensors. These products are offered at standard market prices.

Salt Spray Chamber

Eurovent offer both a cyclic corrosion test chamber eurovent-250 as well as a traditional salt spray chamber , are compatible with multiple test standards including automotive standards and they can be alternated/cycled between varied humidity programs with the traditional salt spray.

In recent years it has been proven that cyclic corrosion tests offer a more realistic simulation of real time corrosive environments than the traditional salt spray testing method. The salts spray test revolves around a single set point of temperature (ambient to 55 Deg) on the continuous mode. It lacks the role of real-life conditions. such as condensation humidity, air-drying etc. making the test less reliable than the cyclic corrosion test. Though offer both variants (cyclic corrosion test as well as salt spray test) of the chamber, it always suggests opting for eurovent-250 as it is programmed to conduct a whole range of corrosion tests such as wet cycle, dry cycle, controlled humidity as well as the salt spray test in a single chamber

Corrosion testing involves multiple test standards, which are developed by the automobile manufacturers or are according to the specific country standards. To match this diversity, eurovent has engineered both its to comply with more than 100 global test standards. It has a mix of all types of test standards ranging from ASTM, MIL, ISO, JASO to GM, NFX, AS, ECC and more.

Eurovent Salt Spray Test chamber meet the requirements of basic, continuous salt spray tests conducted at a single temperature only, such as ASTM B117 and similar international test standards, and may be used with pH neutral salt solutions (NSS) or those acidified by the addition of Acetic Acid (ASS) or Cupric Acid (CASS) these are specified in ISO and other standards around the world. Salt spray tests are widely performed for various purposes such quality control and corrosion resistance comparison.

Salt Spray Chamber is a test cabinet which is used for conduction neutral salt spray test or NSS Test on meta surface coatings. It is used for checking the resistance of the coating towards corrosive environment. The salt spray tester generates an accelerated form of salt laden environment inside which the specimen are tested for its quality.

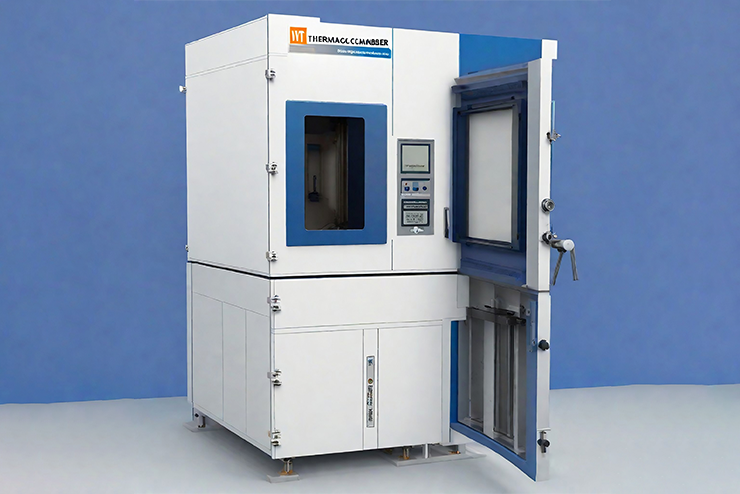

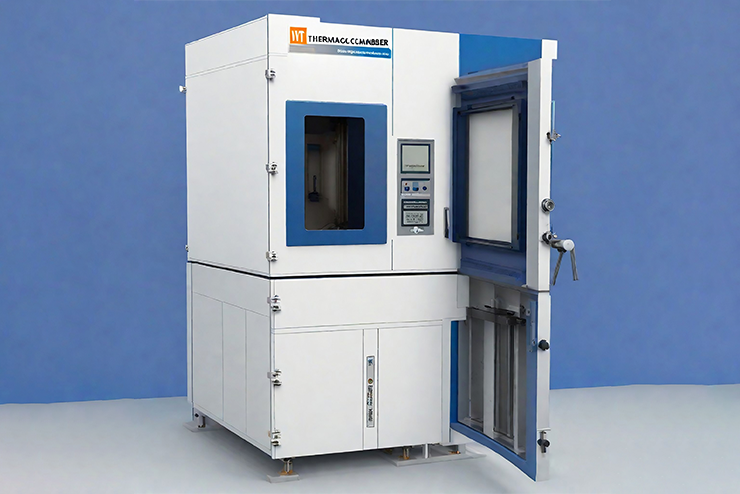

Thermal Shock Chamber

Thermal shock thermal shock chamber meets all of the major international test standards such as MIL-883H, MIL-202G -107G, JESD22-A104D, IEC 60068-2-14, JASO D014-4, EIAJ ED-2531A and JIS C 60068-2-14.

The thermal shock chamber has two zones namely the hot zone and the cold zone. The specimen is kept on the test basket, which is transferred between the hot & cold zones through a motorized system connected by a screw rod. It is primarily used to study the impact of the rapid change of temperature on the specimen. In real world scenarios, such rapid change in temperature causes cracking of the material, the mechanical failures and permanent change in electrical performance. It is therefore important to study and analyse such failures to design a better product in order to withstand such changing environmental conditions.

thermal shock chamber has recently undergone a series of technology upgrades to reduce the overall test time and to shorten the temperature recovery time while maintaining high uniformity. The result thus obtained shows consistent accuracy in temperature recovery and uniformity across multiple test cycles thereby improving the test reproducibility and reliability characteristics of the chamber. Inside the chamber, the hot and cold zones are sealed with specially designed gaskets to minimize leakage between the two zones. The Specially designed test basket of low thermal mass with a powerful temperature-conditioning unit enables the chamber to achieve faster recovery rates.

Thermal shock chamber can also be customized as per the test requirements.

Dust chamber

Dust Test Chamber simulates dusty environment to validate the reliability and functioning of specimen under extreme environment. Being an ideal option for testing electronics and automotive components, the chamber’s dust composition, dust concentration levels, test duration and dust injections, controlled air velocity to the test space are exclusively designed to comply with the MIL-810F test standard procedure I and procedure II.

The interior of the chamber is built with 304 grade stainless steel treated for erosion resistance and high temperature application to avoid creep failure. The exterior body is made of GI with electrostatic powder coating offering high wear resistance. It’s all systems as well as the sub-systems are shielded to provide protection from sand and dust particles. The test space is fitted with externally controlled turn table to rotate the specimen in any direction which could bear a weight up to 150 kg. The viewing window in test space is provided with wipers for user to view the specimen under testing.

Rain Test Chamber

The Drive-In Rain Test Chamber is generally used to conduct whole body testing of assembled vehicles under different rain test procedures to study and estimate their structural degradations and destructions induced by rain/water. The twin shower area with 1.1 million litre & 0.35 million litre volume is enclosed in a shed where arrays of pipes are interconnected to form zones to ensure the uniform spraying as per JSS 55555 test standard. The water gushes through the nozzle at a flow rate of up to 288 cu m/hr and the test chamber water collection system have a central grating with sufficient slope to collect the sprayed water during operation and circulate it back to the water reservoir to ensure close loop circulation.

The Driving rain test facility is divided into multiple zones. The operation of these zones is as per the requirement of JSS-55555. Number of zones for “Shower No.1” is 4 (5 meter width for each zone) and for “Shower No.2” is 2 (5 meter width for each zone. SCADA based report generation/monitoring system is provided for water flow rate, water pressure versus duration in graphical and tabular format.

Altitude Chamber

Aircraft and its components are subject to extreme pressure and climatic conditions during flights. These parameters have a significant influence on the functioning of individual components, and they must be monitored and measured for safety reasons. Altitude chamber allow for the testing of aerospace components in an environment with controlled pressure, temperature and humidity parameters. An altitude of 100,000 feet [10 mbar] can be simulated in the test space.

As rightly quoted “Good engineering is a perquisite for reliability”, a lot of detailing has gone in both the system designing and the component selection of the . These technologies require the utmost reliability of the components and systems on board, since human lives are often entrusted to them. Be it in refrigeration system comprising the semi hermetically sealed reciprocating compressor, high efficiency evaporator unit, in-built water-cooled condenser, on-Demand cooling, et all. are all carefully designed to offer the best reliability to the customer. The chamber can offer altitude ranges of up to 150,000 feet[1mbar] optionally as well. The Altitude chamber can also be customized as per the test requirements.

Walking chamber

Home Appliances especially refrigerators are constantly under scanner to be more energy efficient, reliable and environment compliant. This has led many manufacturers to bring new innovations in their product line-up. Many such manufacturers are using to test their new products for its cooling performance, energy efficiency and construction reliability under various environmental conditions.

The featured Walk-In Chamber has test space capacity of 25,344 Litres, temperature range of -15°c to 50°c and humidity range of 10%RH to 98%RH. The test chamber has two port holes for live product testing with rate of change of heating/cooling 0.2 °c (with mass) and controlled airflow rate of 0.5m/s. The energy efficient chamber is customisable as per customer’s requirement with 24X7 customer support and is available in 18 countries.

We ensure safety while you are testing your product. Safety systems like fire suppression system, gas monitoring systems and safety evacuation of the gases from the system.

Integration chamber

Vibration and Temperature environmental chambers on Lifting test space are widely endorsed by their users because of their ability to adapt to various shakers, test modes combinations with high temperature, low temperature and humidity. These environmental chambers, realized upon specifications, are dedicated to Vibration Temperature and Humidity combined tests.

Even smaller electronic devices and more diverse operating and installation environments are making devices increasingly vulnerable to direct effects from vibrations, and electrical device vibration testing has grown in importance as a result. Combined-environment testing combines vibrations with various environmental stresses such as a low-temperature environment, high-temperature environment or high-temperature/humidity environment. It is a type of testing that recreates environments that more closely approximate actual operating environments.

Tests volumes are optimized according to the geometry, the nature, the mass and the dissipation of the product to be tested, while using a vibrating element. These environmental chambers are adapted standards. The flexibility of the manufacturing process enables to build environmental chambers set on motorised lifting test space. The shaker can be fixed and the environmental chamber can be positioned on the top of it. Associated with a lateral transfer system.

To meet with these features, our manufacturing process integrates the drawer principle, equipped with a head expander that ensures the tightness between the shaker and the environmental chamber and that can be adapted to several shapes.

These chambers meet a variety of MIL-STD, ASTM, and other test standards.